Let’s be honest—packaging costs can sneak up on you. One minute you’re ordering a few drums or boxes, and the next, your overhead costs have skyrocketed.

What if you could significantly reduce those expenses without compromising the product quality or your brand reputation? Welcome to the world of bulk bags (FIBCs).

Quick Teaser:

- FIBC cost per kg: R0.90

- Drum cost per kg: R2.40

- Savings per ton: R1,500+

This guide is for procurement managers, warehouse supervisors, and operations teams who want to:

- Lower variable costs

- Improve inventory management

- Calculate ROI before making a change

- Adopt more eco-friendly packaging options

Feel free to jump straight to the interactive calculator below or read through this comprehensive guide.

Section 1: Meet the Contenders – What Are Bulk Bags (FIBCs) and Alternative Packaging?

Let’s define them simply:

- Bulk Bags (FIBCs): Flexible Intermediate Bulk Containers made from woven polypropylene. Ideal for dry, flowable goods.

- Alternative Packaging: Drums (metal/plastic), cartons, rigid bins. Often heavier and more rigid.

Where They’re Used:

- FIBCs: Agriculture, chemicals, construction, food production

- Drums/Boxes: Pharmaceuticals, oil & gas, specialized transport

Packaging Design + Utility:

- FIBCs use less raw material overall and maximize utility with stackable, collapsible shapes

- Drums and cartons take up more space, both empty and full

Vaal Bulk Bags is a leading South African supplier of FIBCs. We help companies across the country optimize packaging, reduce costs, and boost efficiency without compromising safety.

💡 Fun Fact: A single FIBC can replace over 40 standard sacks. That’s less packaging, minimizing waste, and faster handling.

Section 2: Crunching the Numbers – Bulk Bag Cost Analysis vs Drums and Boxes

Let’s calculate the side-by-side numbers.

Materials Costs Per 1000kg of Product:

- FIBC (Reusable 5x): R900

- Drums (Single-use): R2,400

- Cartons (Single-use): R1,950

Long-Term Cost Breakdown:

| Packaging | Year 1 | Year 3 | Year 5 |

| FIBC | R900 | R1,800 | R2,700 |

| Drums | R2,400 | R7,200 | R12,000 |

| Cartons | R1,950 | R5,850 | R9,750 |

✅ Mini-Calculator Snapshot:

- Enter your volume, cost per unit, reuse cycle

- Get instant cost savings projections

Section 3: The ROI Breakdown – How to Calculate Real-World Savings

Let’s talk profit margins.

Reusable packaging means you buy once and use it several times. The initial investment might be slightly higher, but the long-term ROI is unmatched.

Use Our ROI Calculator Tool:

- Input: Packaging type, volume, reuse cycles, labor cost

- Output: ROI metric, break-even point, annual savings

Case Example:

- A manufacturing plant switched from drums to FIBCs

- Cut packaging spend by 52%

- Increased productivity by reducing loading times

- Resulted in significant savings year after year

Section 4: Hidden Costs That Add Up Fast (and How Bulk Bags Help Reduce Them)

Let’s look at costs associated with your current packaging:

1. Overhead Costs:

- Warehouse space (FIBCs stack better)

- Admin/recording time

- Maintenance expenses and equipment needs

2. Variable Costs:

- Constant reordering

- Single-use waste = higher packaging costs

- Shipping costs increase due to inefficient use of space

3. Labor Savings:

- Quicker loading = less salary and fewer shifts

- Improved operational efficiency

- Lower payroll taxes and admin time

Example: A distributor cut labor costs by R45,000 annually by automating palletizing using custom FIBCs

.

Section 5: Big Picture Thinking – Reduce Packaging Waste, Boost Productivity

Here’s how you can reduce packaging and still improve output:

- Reusable FIBCs reduce the amount of material consumed

- Fewer shipments needed → reducing shipping costs

- Cleaner warehouse space = streamlined inventory management

Bonus: Aligns with eco-conscious consumers who value sustainable practices

Eco Perks:

- Less material waste

- Smaller carbon footprint

- Great for your brand reputation

Section 6: The Innovation Factor – Packaging as a Driver of R&D and Growth

Packaging isn’t just about containment—it’s a tool for growth.

- Smart packaging design supports safer transport, faster delivery

- Companies using automated FIBC systems boost productivity 20%+

- Sparks research and development in load optimization

Track-It-All helps streamline the production process and allocate resources efficiently. Our clients use our systems to monitor utility, manage procurement, and forecast supply chain needs in real time.

💡 Use Case: A client introduced eco-friendly materials + FIBCs = reduced spoilage, fewer overhead expenses, and improved customer satisfaction.

Section 7: Ready to Switch? Here’s What to Do Next

If you’re ready to take the next step:

- Calculate your current packaging spend

- Use our ROI metric to compare options

- Identify opportunities to reduce overall costs

Pitch Tips:

- Highlight cost savings in business costs and inventory costs

- Show how you’ll leverage reusable systems

- Emphasize reduced costs without compromising safety or quality

📞 Talk to Our Team or request a discounted packaging audit to assess where you can optimize

Sidebar Tools You Can Use:

- 🧮 ROI Calculator

- 📊 Packaging Cost Comparison Chart (Downloadable PDF)

- ✅ Checklist: How to Transition to FIBCs

- 📦 Presentation Template: Bulk Bag Cost Analysis

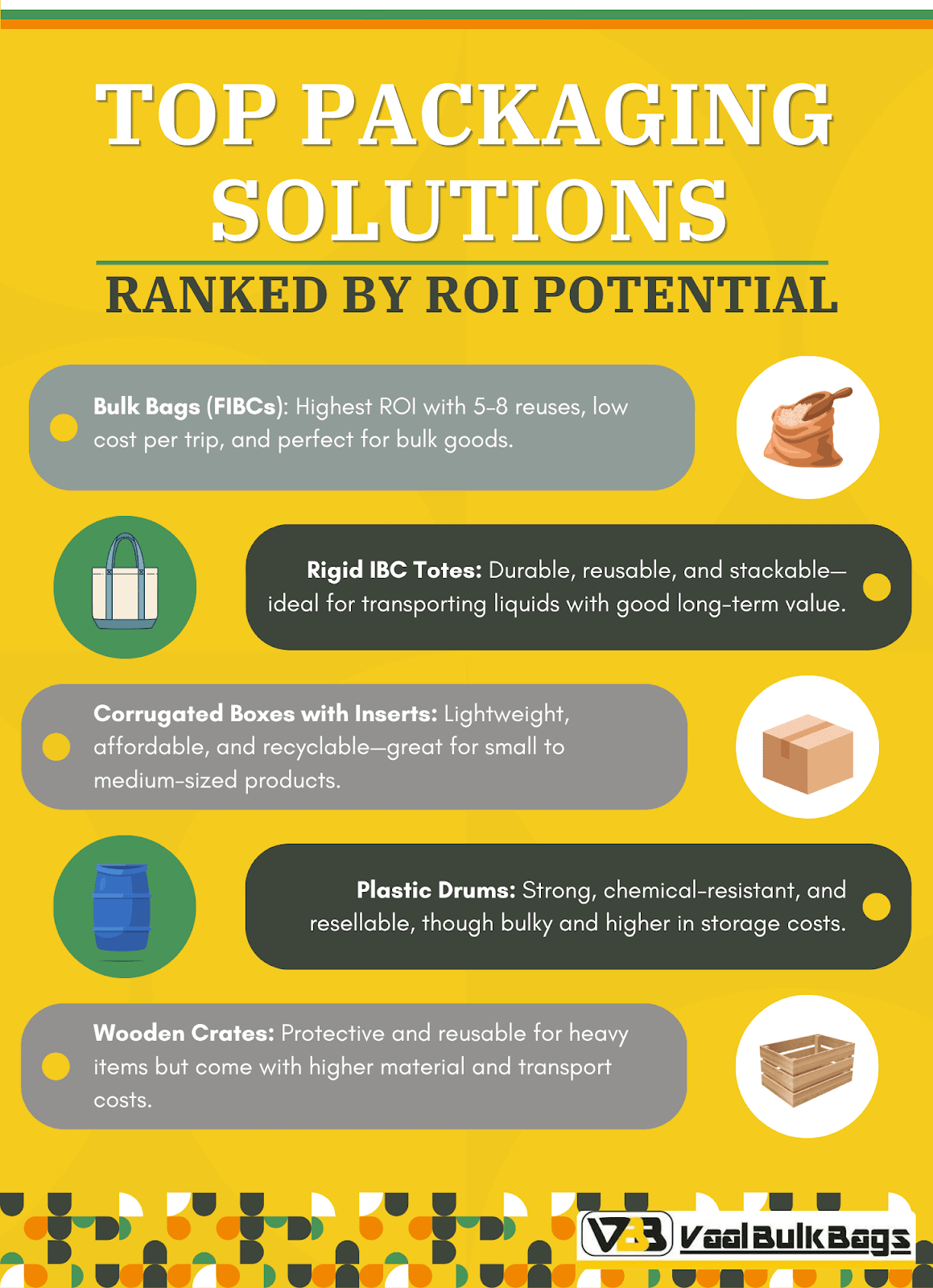

Top Packaging Solutions Ranked by ROI Potential

Frequently Asked Questions (FAQs)

FAQ 1: Why do packaging costs fluctuate so much?

Packaging costs can fluctuate due to changes in the price of raw materials, supply shortages, or unexpected fees from third-party logistics providers. That’s why locking in a stable solution like FIBCs can help with cost management over time.

FAQ 2: How do FIBCs help in reducing waste?

FIBCs are reusable, which means you can reduce packaging waste and lower your production costs in the long run. Unlike single-use drums or cartons, bulk bags are built for durability and better recycling practices.

FAQ 3: Are there environmentally safer packaging solutions?

Yes! FIBCs are among the most environmentally friendly packaging solutions available. They support sustainable practices, use fewer packaging materials, and generate less waste during each stage of production.

FAQ 4: What if my current supplier has higher costs than others?

You’re not alone—many businesses can significantly reduce packaging spend by exploring alternative suppliers. With bulk purchasing, you can also take advantage of better rates without compromising the quality of your packaging.

FAQ 5: Can automation be used with bulk bags?

Absolutely. Bulk bags are designed for automation—whether you’re using conveyors, filling stations, or integrated warehouse tech. That leads to higher durability, minimizing the risk of damage, and smoother, on-demand operations. Furthermore, the efficiency of bulk bags significantly streamlines the supply chain, enabling quicker project turnaround times and reducing labor costs. In industries such as construction, this translates to safer job sites and better resource management. The increasing bulk bag usage in construction has become essential for handling materials like sand, gravel, and aggregates, ensuring that operations run smoothly and effectively.

FAQ 6: What hidden costs should I watch for?

Think beyond just packaging price. Consider costs such as rent, damaged goods, and downtime. FIBCs help cut those higher costs by streamlining space, improving safety, and reducing time lost across each stage of production.

Conclusion: Let the Numbers Do the Talking

If the goal is to increase profit and boost profitability through smart, sustainable choices, bulk bags are a no-brainer. Investing in bulk bags not only reduces packaging costs but also minimizes waste, aligning with environmentally friendly practices. Additionally, understanding the importance of labels for bulk bags ensures that products are easily identifiable and compliant with regulations, further enhancing operational efficiency. By prioritizing smart packaging solutions like bulk bags, businesses can successfully drive profitability while supporting sustainable initiatives.

You can significantly reduce your packaging, streamline the supply chain, and hit new benchmarks for sustainable production.

Now’s the time to forecast smarter and adopt solutions that align with where the packaging industry is headed.

Encouragement:

- Use the calculator to run your own numbers

- Or get in touch with Vaal Bulk Bags, a trusted supplier ready to help you save big.

📩 At Vaal Bulk Bags, we’re proud to support South African businesses with durable, eco-friendly packaging options. Reach out today to explore how we can help you reduce costs and optimize performance—without compromising quality. Our commitment to quality assurance in bulk bag manufacturing ensures that every product meets the highest standards of reliability and sustainability. By partnering with us, you not only benefit from innovative packaging solutions but also contribute to a greener future. Let’s work together to enhance your supply chain while staying environmentally responsible.