When it comes to heavy-duty packaging, every detail matters. A bulk bag—also known as a FIBC bag—is designed to handle bulk items like sand, grain, chemicals, and powders. These bags are widely used in industries such as agriculture, mining, and construction because they’re strong, efficient, and reliable. The versatility of bulk bags extends to their ability to be manufactured for specific applications, including foodgrade versus feedgrade bags. Foodgrade bags meet stringent health standards, making them suitable for transporting consumables, while feedgrade bags are designed for agricultural products meant for livestock. This distinction ensures that industries can choose the right type of bag to maintain safety and compliance with regulations.

But here’s the catch: bag capacity and weight capacities must be carefully considered. Using the wrong size, underestimating the maximum weight, or exceeding the SWL (safe working load) can put workers, equipment, and products at risk.

That’s where trusted suppliers like Vaal Bulk Bags step in. Based in South Africa, they deliver custom bulk bags and bespoke FIBC solutions that are ISO-certified, food-safe, and tailored to every industry. With decades of experience, their team helps businesses selecting the right bulk bag for safe and efficient operations.

Understanding Bulk Bag Basics

So, what exactly is a bulk bag?

- It’s a large, woven sack made from woven polypropylene fabric.

- Also called flexible intermediate bulk containers (or simply known as FIBC).

- Bulk bags are designed to hold and transport thousands of kilograms of bulk material.

Common uses include:

- Construction (sand, gravel, cement)

- Agriculture (grain, fertilizer, seeds)

- Chemicals (powder, minerals)

- Food and pharma (sugar, starch, recycling materials)

Standard bulk bags come in general shapes and dimensions, but many businesses require a specific bulk bag design to avoid the risk of bag failure. That’s where bespoke FIBC options deliver a safer and more efficient outcome. By customizing the design and construction of these flexible intermediate bulk containers, companies can ensure maximum performance tailored to their specific materials and handling processes. For those looking to delve deeper into this topic, various fibc bulk bag types explained can provide valuable insights into choosing the right solution for their needs. This knowledge not only enhances safety but also optimizes logistics and transportation efficiency.

Bulk Bag Capacity Explained

When people talk about bulk bag capacity, they usually mean how much volume or weight a bag can hold. This measurement is crucial for various industries, particularly in shipping and logistics. Understanding bulk bag weights helps companies determine the optimal load for transportation and storage while ensuring safety and compliance with regulations. Additionally, it aids in selecting the right type of bag for specific materials, maximizing efficiency and preventing possible product damage.

- Capacity is often measured in cubic feet or cubic meters.

- Fibc volume directly connects to space inside the bag.

- But remember: volume ≠ weight.

For example:

- 1 cubic meter of feathers weighs far less than 1 cubic meter of sand.

- That’s why weight limits and rated safe working load are critical.

This is where businesses need a capacity calculator or volume calculator to check how much volume a bag can hold safely.

How to Use a Bulk Bag Capacity Calculator

A calculator can help businesses figure out exactly how much their bag allows. Here’s a simple process:

- Measure dimensions and weight: length × width × height.

- Multiply to get the total cubic volume.

- Use a calculation tool or capacity calculator to convert cubic feet into kilograms or pounds.

- Compare the result against the rated safe working load (SWL).

Example:

- A 1-ton fibc bulk bag may measure 35″ × 35″ × 40″.

- That equals about 32 cubic feet of space.

- The calculator to estimate tells us sand (high density) will quickly reach the maximum weight, while lighter products may not.

This product weight guide is essential for safe use, because exceeding the SWL can cause serious bag failure.

Key Factors in Bulk Bag Design

A perfect bulk bag solution depends on several design choices:

- Fabric strength: Most bags are made of woven polypropylene, tested at 5:1 or 6:1 safety factors.

- Liners: A liner is often added for powders, food safety, or moisture protection. Food-grade liners are common in pharmaceuticals and food storage.

- Spouts: An open top or spout top design helps with easy filling and discharge. Spout top bags are ideal for controlled filling.

- Lift loops: Strong lift loops allow forklifts or cranes to handle the load securely.

- Shape: Some bags maintain a square shape when filled, which helps stacking and pallet stability.

These options allow bags to transport materials safely, making them ideal for loading and unloading tasks in warehouses and production sites. Moreover, using bags with dedicated compartments can significantly enhance organizational efficiency during these tasks. This is where the importance of document pouches comes into play, as they help keep important paperwork secure and easily accessible. Ensuring that all materials, including essential documentation, are effectively managed contributes to streamlined operations and reduced errors in busy environments.

When to Specify Custom Bulk Bags

While standard bulk bags work for common jobs, certain industries need custom bulk bag design.

Examples include:

- Fragile or high-density products (where a liner and reinforced seams are vital).

- Long-term outdoor storage (UV-protected polypropylene fabric required).

- Export compliance (meeting international transport safety standards).

- Powders or flowable materials that demand controlled filling.

Case study insight: A mining company switched from used bulk bags to bespoke FIBC bags with extra-thick fabric and moisture-resistant liners. This reduced the risk of bag failure, increased safety, and helps reduce wastage. The company also noted enhanced durability during transportation and handling, leading to fewer disruptions on site. As a result of these improvements, they began recommending bespoke FIBC bags not only for mining but also for bulk bags for construction projects, recognizing the advantages across various industries. The transition has become a model for others looking to optimize their operations and improve safety standards.

Choosing the Right Bag for the Job

What’s the right bag? Here are some quick pointers:

- Sand or gravel → Heavy-duty bag with strong lift loops.

- Grain or fertilizer → Liner with spout top for easy filling.

- Chemicals → Anti-static type C bag with proper liners.

- Light products → Bags that maintain a square shape for stable stacking.

Quick table comparison:

| Product Type | Right FIBC | Why |

| Sand | Fibc bag with strong fabric | Handles maximum weight safely |

| Grain | Custom bulk bag with liner | Prevents leaks and contamination |

| Fertilizer | Spout top design | Bag allows efficient handling |

| Chemicals | Type C FIBC | Anti-static and safe and reliable |

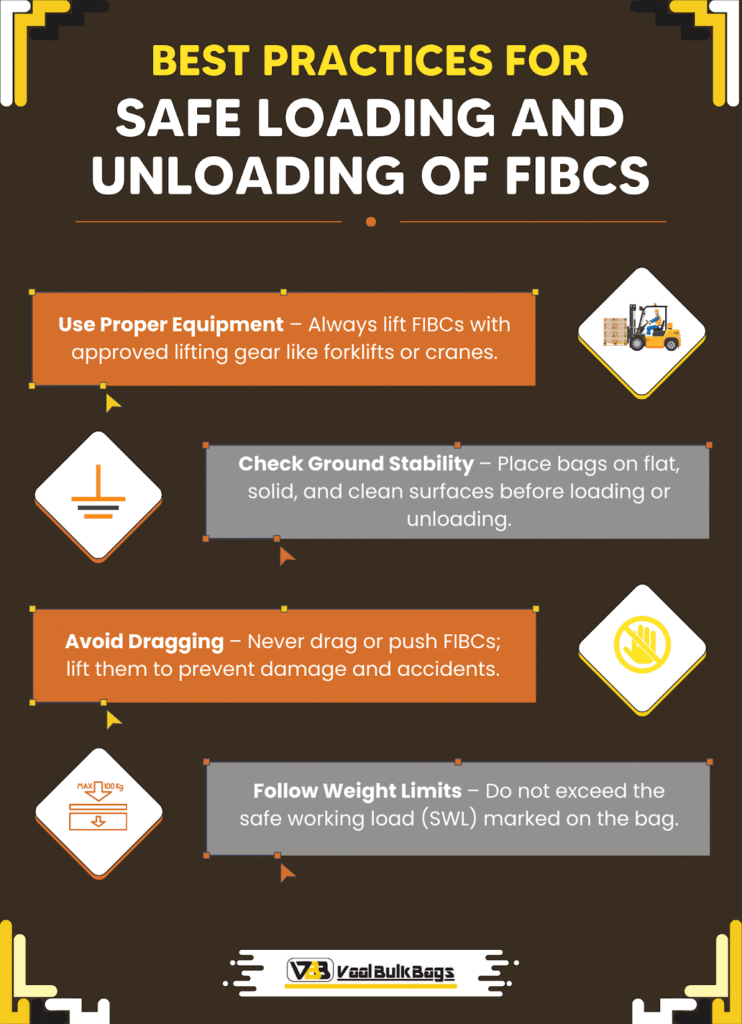

Safety Guidelines: Load and Weight Capacities

Safety should never be compromised. Follow these tips:

- Always check rated safe working load before loading and unloading.

- Never exceed the maximum weight.

- Stack carefully on a pallet to safely transport and store.

- Avoid sharp objects or overfilling—both increase the risk of bag failure.

- Use proper filling equipment to ensure safe handling.

Remember: exceeding the SWL can lead to bag failure, workplace injury, and product loss.

Quick Comparison: Standard vs. Custom Bulk Bags

| Feature | Standard Bulk Bags | Custom Bulk Bags |

| Price | More affordable | Higher upfront, but better ROI |

| Flexibility | Limited options | Designed for specific bulk needs |

| Durability | General quality | Stronger, tailored, safe and reliable |

| Compliance | Basic | Meets international transporting and storing rules |

| Fit | Average | Tailored for a solution for your product |

Why This Business is the Right Choice

For businesses in South Africa, Vaal Bulk Bags is the bulk bag company trusted by leading industries. They appear in credible directories, hold ISO and BRC certifications, and are well-reviewed by clients who praise their reliable service.

Their reputation in the bag industry is built on bulk bag design, safety, and cost-effective delivery. They are also listed as a bulk bag manufacturer that provides both new and refurbished options, making them stand out among competitors.

Top Reasons to Choose Vaal Bulk Bags

- Expertise in custom bulk bags and bespoke FIBC design.

- Proven record across construction, mining, agriculture, and food.

- Transparent weight and volume testing with certifications.

- A strong name in bulk bag industry reputation and reviews.

- Offers bulk bags for sale that balance cost with premium safety.

Get the Right Bag Capacity Calculated

Not sure what the right bulk bag size is? A calculation tool session with an expert will solve it.

- Get a capacity calculator demo.

- Learn which bag allows safe handling for your product.

- Discuss the best bag design for your business needs.

Request a free consultation with Vaal Bulk Bags today and get your right FIBC designed for total safety and efficiency.

Best Practices for Safe Loading and Unloading of FIBCs

FAQs: Bulk Bag Needs Answered

Q: How do I calculate the capacity of a bulk bag?

A: Use a volume calculator by multiplying dimensions. Compare with the rated safe working load to avoid exceeding the SWL.

Q: Can I order small runs of custom bulk bags?

A: Yes, many bulk bag manufacturers offer flexible orders.

Q: What liner should I use for chemicals or food products?

A: Choose a liner suitable for moisture or powder protection—food-grade for consumables, anti-static for chemicals.

Q: How long can a bulk bag last in outdoor storage?

A: With UV-protected polypropylene fabric, bags can last months outdoors.

Simplify Bulk Bag Decisions with Expert Help

Choosing the right bag doesn’t need to be overwhelming. With Vaal Bulk Bags, you get the perfect bulk bag solution—safe, reliable, and tailored to your fibc needs.

Ready to simplify your packaging? Connect with the expert team at Vaal Bulk Bags today. They’ll design a solution for your product that ensures safety, efficiency, and peace of mind.