In high-volume South African industries, things need to move fast — but they also need to move safely. From fertiliser on farms to aggregates on construction sites and food or chemicals in factories, bulk bags are doing the heavy lifting behind the scenes every single day.

At Vaal Bulk Bags, we work closely with businesses handling millions of tonnes annually, and we see firsthand how much difference proper bulk bag handling makes. When bulk bags are handled correctly, operations run smoother, downtime drops, and safety improves. When they’re not, the risk of accidents, spillage, damaged products, and injured staff increases quickly.

We don’t just supply bulk bags. We help businesses understand how to use them properly, efficiently, and safely. This guide shares practical, real-world advice for bulk bag handling operations, shaped by South African working conditions and the realities of high-volume environments.

Getting to know bulk bags (and why handling matters so much)

Bulk bags — also known as Flexible Intermediate Bulk Containers, or known as fibcs — are designed to move and store large volumes of dry bulk materials efficiently. Globally, more than 3.5 million bulk bags per day are in circulation, adding up to a million bulk bags per year across agriculture, construction, mining, and manufacturing.

Most bulk bags can safely hold between 500kg and two tonnes, meaning they can hold between 500kg and two full tonnes of material per bag. The exact capacity depends on the type of bulk bag, the type of material, and whether the bag meets the ideal design specifications for the job.

That strength, however, only works when bags are handled as intended. Even high-quality bulk bags can fail if they’re overloaded, lifted incorrectly, or stored poorly.

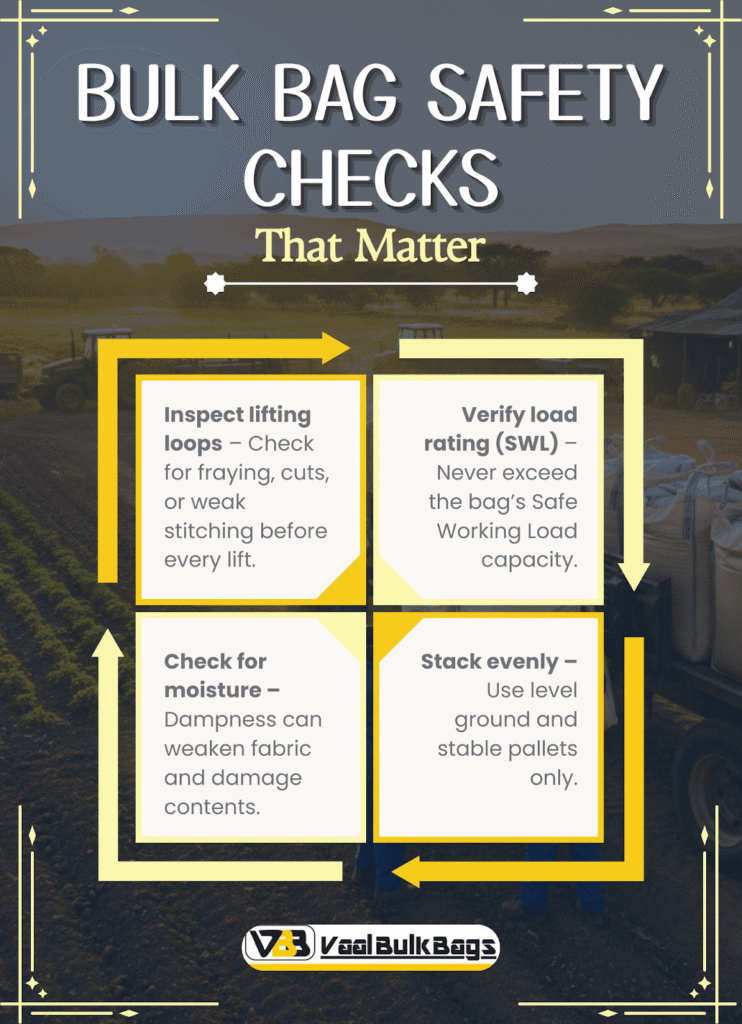

Bulk Bag Safety Checks That Matter

Why bulk bag handling is a safety issue, not just an operational one

Handling bulk bags might look straightforward, but poor practices can quickly lead to accidents and injuries. Incorrect lifting, unstable stacking, damaged lifting loops, and exposure to direct sunlight all increase the chance of failure.

South African businesses must also comply with occupational safety and health requirements, and international guidance from bodies like the National Institute for Occupational Safety reinforces the need for proper handling guidelines.

Good bulk handling isn’t about slowing things down — it’s about reducing the risk, protecting people, and keeping operations running efficiently and safely.

Choosing the right bulk bags for your operation

Not all bulk bags are created equal. Using the right bag for the job is one of the simplest ways to improve safety and efficiency.

When selecting bulk bags, think about:

- The maximum weight required

- Whether the product is dry bulk or moisture-sensitive

- The filling and unloading process

- Exposure to static electricity, especially with powders

- Industry requirements for chemicals and food

- Whether the equipment is steel or stainless steel

Our range of bulk packaging options — including FIBCs, liners, and customised designs — can be viewed on our products page. As a local supplier, we help businesses choose the right bulk bag, not just the cheapest one.

Filling bulk bags properly from the start

The filling process plays a huge role in how a bulk bag performs later on. Poorly filled bags are harder to handle, harder to stack, and more likely to fail.

When filling bulk bags:

- Make sure the handling device or filling frame is correctly rated

- Keep lifting loops straight and untwisted

- Distribute weight evenly as you fill the bag

- Never exceed the SWL marked on every bulk bag

- Watch for static electricity with fine powders

A well-filled bag is a safer bag — and much easier to move through your operation.

Lifting and moving bulk bags safely

Moving filled bulk bags requires the right equipment and the right technique.

Forklifts, hoists, and lifting equipment

- Always lift a bulk bag using all lifting loops

- Inspect loops before every lift

- Use certified lifting equipment rated for the load

- Avoid dragging bulk bags directly across rough floors

- When possible, use a hoist or frame designed for bulk handling

Using a forklift incorrectly is one of the most common causes of damage. Even using a forklift with worn tines can weaken bags over time.

Stacking and storing bulk bags the right way

Storing bulk bags correctly protects both the bags and their contents.

Key storage tips:

- Only stack bulk bags if they’re designed for stacking

- Follow guidance for the stacking of bulk bags

- Keep bags away from prolonged direct sunlight

- Ensure bags are stored on a stable pallet where required

- Maintain a clean, dry area — clutter increases risk

Poor storage of bulk bags can weaken fabric, compromise stability, and shorten bag lifespan.

Bulk bag unloading and discharge systems

Bulk bag unloading is another high-risk stage, especially in busy facilities.

Using a bulk bag unloader or bulk bag discharger improves control and limits spillage. During the unloading process:

- Secure the bag in a certified frame

- Control flow through the discharge spout

- Keep staff clear of suspended loads

Well-managed bulk bag unloading improves safety and reduces product loss.

The dos and don’ts of bulk bag handling

Dos of bulk bag handling

- Follow clear handling guidelines

- Inspect bags before use

- Use correct lifting equipment

- Train operators regularly

Don’ts of bulk bag handling

- Don’t exceed SWL

- Don’t lift damaged bags

- Don’t ignore wear and tear

- Don’t store bags improperly

These dos and don’ts of bulk handling — and the often-overlooked don’ts of bulk bag handling — form the backbone of safe operations.

Best Fit: Who this guidance is for

This guide is ideal for:

- Farms handling fertiliser or seed

- Construction sites moving aggregates

- Manufacturers working with dry bulk inputs

- Warehouses managing high-throughput material handling

If bulk bags are part of your daily workflow, these best practices matter.

Why businesses choose Vaal Bulk Bags

There’s no shortage of bulk bags on the market, but businesses choose us because:

- We’re a trusted South African bulk bag manufacturer

- Our products meet strict quality control standards

- We offer tailored packaging solutions

- We understand local operating challenges

- We support clients beyond the sale

You can see the industries we serve on our bulk bag industries page.

A quick, honest comparison with competitors

Some suppliers focus purely on price. We focus on performance over time. Lower-cost bulk bags may meet minimum specs but often fail sooner, increasing replacement costs and operational risk. Our approach prioritises durability, consistency, and real-world reliability.

Trust signals and reassurance

Our experience, client feedback, and technical insight are shared regularly on our blog. We’re proud to support South African operations with bulk bags that perform where it counts.

FAQ: Bulk bag handling basics

How much weight can bulk bags handle?

Most bulk bags can safely hold between 500kg and two tonnes, depending on design.

Can bulk bags be reused?

Some fibcs are reusable if inspected and approved.

Is outdoor storage safe?

Short-term is fine, but long-term exposure to sunlight should be avoided.

What causes most failures?

Overloading, poor lifting, and incorrect storage.

Safer bulk handling starts with better habits

Bulk bags make modern bulk handling possible — but only when they’re used correctly. By following proven bulk bag handling best practices, South African businesses can protect staff, reduce waste, and improve operational flow.

If you’d like guidance on selecting, handling, or storing bulk bags safely, our team is here to help. Reach out through our contact page for practical, expert advice — no hard sell, just support.