In South Africa’s mining and steel sectors, the demands placed on packaging equipment are uncompromising. Heavy loads, abrasive bulk material, static electricity risks, harsh outdoor storage conditions, and tight supply chain pressures mean that companies need much more than an ordinary bulk bag. They need the right FIBC, engineered for safety, compliance, and operational efficiency.

At Vaal Bulk Bags, we understand these conditions because we work with mining engineers, plant managers, and production teams every day. As a proudly local FIBC manufacturer based in Vereeniging, we produce flexible intermediate bulk containers that are engineered for high-risk, high-load, and high-volume environments. Whether you need cost-effective used bulk bags, ISO 9001-certified polypropylene bags, or custom-designed bag options for specific applications, we help you choose the right FIBC for your operation.

Our full range is available here:

➡️ View all bulk bag types

This comprehensive guide explains FIBC types, type C, type D FIBCs, static control, lifting loop stability, weather protection, and how to choose the right bag for mining and steel applications in South Africa.

Understanding FIBC: What Makes the Right Bag for Mining & Steel

When we talk about an FIBC, bulk bag, or FIBC bag, we’re referring to industrial big bags known as bulk bags or FIBC bulk bags. These bags are designed to store and transport large quantities of bulk goods such as aggregates, ore, slag, clinker, mill scale, recycled metal, chemicals, and powder materials.

Our bags are designed with the South African market in mind—UV-stabilized fabrics, strong stitching, reliable lifting loops, and a safety factor suitable for heavy-duty mining applications.

Mining and steel teams rely on FIBCs because:

- They ensure safe handling of bulk material

- They support efficient bulk material handling

- They optimize storage and transportation

- They maintain reliability under tough conditions

- They meet unique requirements around static electricity, bulk density, and contamination risks

With dozens of bulk bag options available, selecting the right FIBC becomes critical for safety and performance.

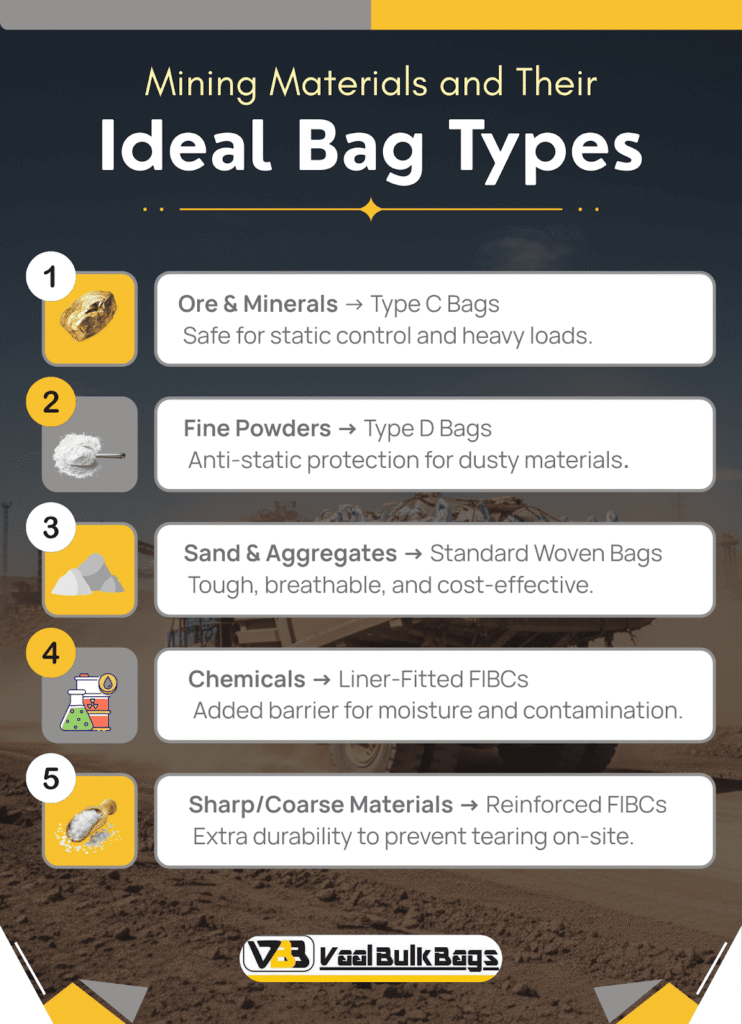

Mining Materials and Their Ideal Bag Types

Types of FIBC Bags: A Quick Classification Guide

South African mining operations require different types of bulk bags depending on material hazards, electrostatic risk, and handling conditions. Below are the types of FIBC bags we manufacture.

1. Type A FIBC (Standard)

Best for: Non-flammable materials with no static risk.

These polypropylene bags are cost-effective, strong, and ideal for general bulk material. However, they are not suitable for environments with flammable gases.

2. Type B FIBC (Low Breakdown Voltage)

Best for: Powders with some ignition risk.

Although not anti-static, they prevent high-energy sparks.

3. Type C FIBCs (Conductive)

Best for: Mining applications with static electricity concerns.

These require grounding to ensure safe handling during loading and unloading. Any type C FIBC we supply comes with strict quality control testing to ensure safety.

4. Type D FIBCs (Anti-static)

Best for: steel and mining industry sites handling volatile powders or working near flammable gases.

Type D FIBCs safely dissipate static electricity without grounding—ideal for operations with unpredictable work environments.

Explore all categories here:

➡️ Bulk bag industries & applications

How FIBC Types Match Mining & Steel Production Needs

1. South African Mining Industry Requirements

Mining operations deal with abrasive materials, high dust concentration, powder behavior, and high bulk density loads. To handle these challenges, bags are made with reinforced seams, UV protection, and advanced static control features.

We help operations choose the right FIBC bag depending on:

- Ore or mineral type

- Bulk density

- Required lifting loop configuration

- Whether the material generates static

- Dust containment standards

- Storage and transportation requirements

This approach guarantees that the bags are durable, compliant, and safe.

2. Steel Production and Metal Processing Needs

Steel plants rely on FIBC containers for slag, alloy powders, lime, chemicals, scrap, and refractory materials. When handling fine powder, we customize:

- baffle bags for shape retention

- coated polypropylene fabrics

- dust-proof seams

- food-grade options (for lime and chemical purity)

- bag type variations for safe stacking

This gives production teams reliable options based on specific applications.

Selecting the Right FIBC for SA Conditions

South Africa’s climate—sun exposure, humidity, rain, coastal corrosion—affects bag performance. When selecting the right container, consider:

- UV resistance of polypropylene

- Fabric coating thickness

- Bag ventilation vs. sealed construction

- Outdoor storage durations

- Total cost of ownership vs. upfront cost

- Whether reusable solutions can work

- Level of customization needed for bulk handling

We help you choose the right bag for your weather and operational conditions.

Why Vaal Bulk Bags Is the Best Fit for Mining & Steel Clients

Clients in mining and steel choose us because:

- Proven reliability — Our ISO 9001 systems ensure that each right FIBC bulk bag meets international standards.

- Local advantage — Faster lead times, daily deliveries, and expert consultations.

- Custom designs — We produce bag applications matched to your exact needs.

- Sustainability — We offer used bulk bags, refurbished options, and recycling programs.

- Competitive pricing — Our mix of virgin polypropylene and refurbished options gives you cost-effective choices.

Learn more or request a quote here:

➡️ Contact our expert team

Quick Comparison: Vaal Bulk Bags vs. Other Suppliers

| Feature | Vaal Bulk Bags | Typical Competitor |

| ISO 9001-certified | ✔ Yes | Often not |

| Custom engineering | ✔ Included | Additional cost |

| Fast delivery (Gauteng base) | ✔ Daily | Once or twice weekly |

| Static-safe Type C & D | ✔ Available | Limited |

| Refurbished options | ✔ High-quality | Usually unavailable |

| SA mining expertise | ✔ Deep experience | Varies |

We consistently appear in reputable platforms and directories across South Africa, and our clients regularly leave positive reviews highlighting reliability, fast communication, and strong product performance.

FIBC for Bulk Packaging: Technical Considerations

Every fibc, fibcs, or jumbo bag must be chosen based on engineering principles:

1. Safety Factor (SF)

Mining and steel clients often use 5:1 or 6:1 safety factors to ensure that the bags can hold large quantities safely.

2. Lifting Loop Configuration

We offer multiple loop styles, ensuring compatibility with cranes, forklifts, or automated loading systems.

3. Bulk Density & Material Flow

Your material’s bulk density determines the best FIBC design, sleeve size, and discharge spout.

4. Static Electricity Management

Avoid accidents by matching the right type—especially type C or type D FIBCs.

5. Jumbo Bag Manufacturing & FIBC Production Standards

Our in-house FIBC manufacturing team follows strict quality control, testing every batch for stitching integrity and load uniformity.

FAQs: Quick Answers for Mining & Steel Teams

1. What is the right FIBC bag for high-risk mining environments?

Typically, type C or type D FIBCs, depending on your static electricity conditions.

2. Are bulk bags reusable?

Yes, many bulk bags also come in reusable formats if they maintain a proper safety factor.

3. What materials are bulk bags made from?

Mostly woven polypropylene, selected for durability, strength, and reliability.

4. Do you supply custom bag designs?

Yes — our customization services allow us to tailor FIBCs to unique requirements.

5. Do you ship nationwide?

Yes — we offer daily deliveries throughout South Africa.

Conclusion

Whether you’re handling abrasive ore, hazardous powders, steel additives, slag, or high-density raw materials, the key to safe, efficient, long-lasting performance is choosing the right FIBC. As a reputable FIBC supplier, we help you match the type of FIBC, fabric strength, anti-static features, and structural components to your exact operation.

At Vaal Bulk Bags, we don’t just offer trusted bulk packaging solutions—we help optimize your bulk material handling, reduce downtime, and lower your total cost of ownership. If you’re ready to upgrade to the right solution, we’re here to help.